What is debossing?

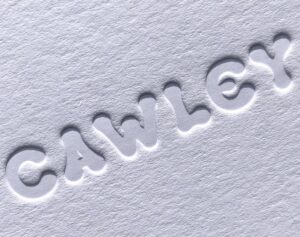

Debossing is the opposite of embossing as it creates an indent in the product. A metal die is stamped onto the front of the product, causing depressions that leave the design imprinted on the product. The indented design can be filled or alternatively be left also known as blind deboss.

This process is popular for giving printed pieces a fresh, contemporary feel. The procedure requires the use of two dies made of materials such as magnesium, copper, or brass. One of these dies is raised, while the other is recessed. These dies fit together in such a way that, when paper is pressed between them, the raised die impresses the paper into the recessed die, leaving behind a lasting debossed impression.